- Kite

- Wing

- Race

- Snow

- More Ozone

The Edge V12 stays true to its original remit of delivering adrenaline-fuelled sessions for riders that crave real power, speed and insane lift; the electrifying reasons that so many get bitten by the kiteboarding bug in the first place!

Find a dealerExperience a world of power at your fingertips. Since inception in 2007 the Edge has been purpose built to provide the ultimate freeride experience, capable of heartstopping riding speeds and gravity defying big air performance.

After 16 years of refinement the V12 also offers a handling quality that will supercharge the sessions of any intermediate twin-tip rider, not just the super high flying renegades!

The V12 represents the continued development of a genuine kiteboarding icon. Two years after the launch of the V11, the refinements in the V12 will only increase the enjoyment of anyone who already loves the Edge’s unique performance possibilities.

If you’re yet to experience the Edge’s powerful personality, there’s never been a better time to jump into the cockpit. The V12’s aerodynamic developments offer even more control and responsive feel for the pilot than ever before.

The Edge has always provided mind-altering experiences in strong winds, but the advantages of transverse shaping and the V12’s clean and taut canopy profile also deliver sublime experiences for those looking to enjoy powder-like freeriding in lighter conditions, too.

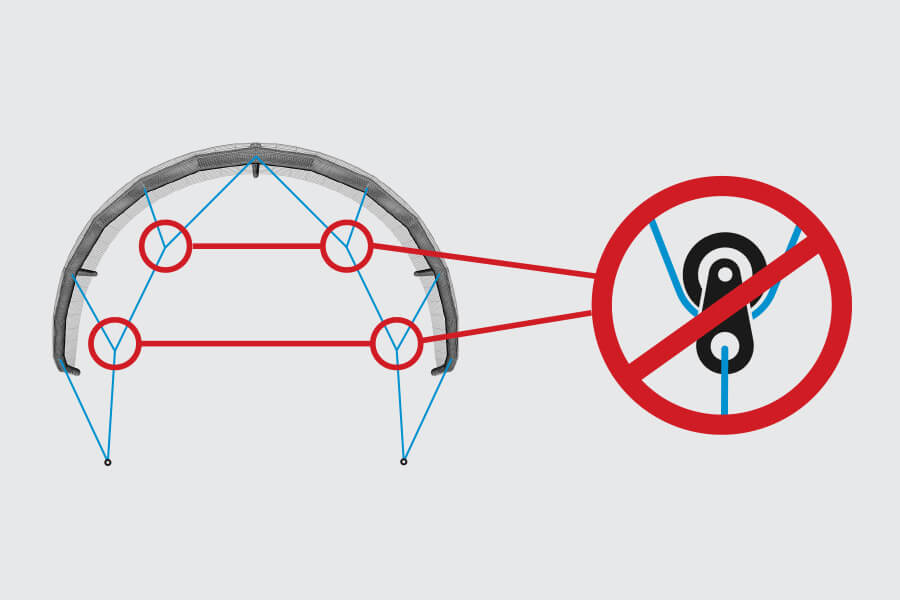

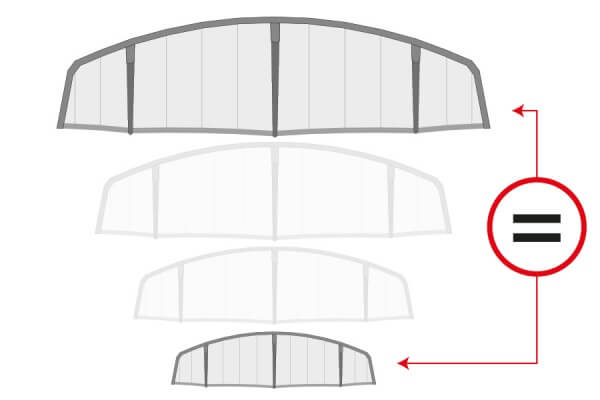

The V12 retains a similar DNA to the V11 with the increased canopy tautness that we have since implemented in the Enduro V4, Reo V7 and Reo V7 Ultra-X thanks to the introduction of transverse sail shaping in the canopy cloth that runs parallel with the leading edge.

Less visually obvious, but noticeable in improved bar feel, a pre-loaded leading edge adds additional tension into the canopy which forms a tighter shape, bringing more rigidity and less sail flutter.

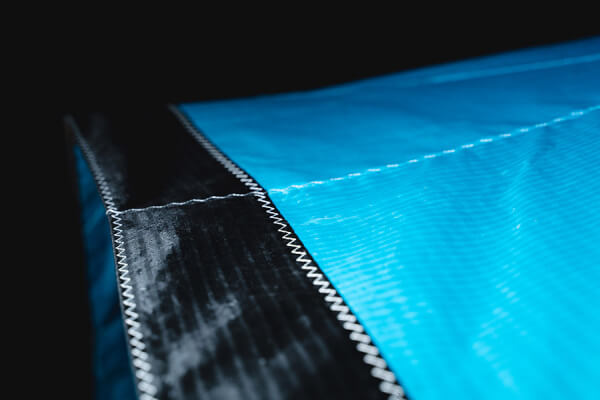

Applying the experience of our paragliding design colleagues, the Edge V12 features an extra seam in the sail running close to the leading edge, which allows for more true 3D shaping.

Our primary focus is always centred around aerodynamic performance and the biggest aerodynamic gains come from being able to maintain the cleanest aerofoil and tightest canopy at all times. Searching for as tight a canopy as possible is a continuous journey.

Not only have we managed to add more profile curvature through transverse shaping, but we’ve also added more strength in the high lift zone thanks to the extra seams.

While the overall ride is a smoother sensation, the bar feeling and feedback is now more precise too thanks to canopy flutter having been reduced. The Edge V12 maintains a cleaner sail and increased airfoil performance in all situations, which is especially noticeable when steered hard and fast.

The Edge V12 drives further upwind while also retaining more feeling and bar feedback when the kite is at the edge of the window as the canopy luffs later (delaying the point at which the canopy starts to flutter and lose power; increasing range).

Ram air foil kites started to take over the elite racing scene after that, when kites like the Ozone R1 became the racing machine of choice. The Edge’s fast riding speeds and tremendous power management continued to enthral, however…

Over the coming years the Edge continued to prove itself one of the most versatile kites when it came to the application of power, weaponizing big air freeriders, speed kiting record hunters as well as future racing stars when it became the official kite for the IKA Under-21 A-class race category, which it still is today.

The smooth combination of speed and power will amplify the enjoyment of any freerider looking for the ultimate sensation of escape.

In the hands of riders like Jamie Overbeek, however, the Edge is also a verified 36 metre boosting behemoth capable of reaching for the stars.

As ever, the ‘Born Light: Genetically Strong’ ethos is applied through every stage of manufacturing. Thanks to the advantage we have in owning our own factory in Vietnam, where 1000 skilled workers apply their careful skill and attention, Ozone products are guaranteed to provide incredible aerodynamic performance with built-in strength.

All you’ll ever find on our kites is exactly what’s needed to meet a rider’s performance demands; nothing more, nothing less.

Ozone uniquely owns its own factory where all kites, wings, boards, hydrofoils, paragliders, speed wings and accessories are made. Guaranteeing hand checked quality control and the finest materials at every step, there are also excellent working conditions for all 1000 employees.

The future is now. All Ozone kite and wings are designed with our own highly advanced custom built CAD software that we control and modify with each new product design. Allowing for specifically tailored technical developments, our designers can maximise performance while also minimising waste.

Teijin is the world’s leading supplier of technical performance materials for marine sports, setting the benchmark in quality with proven superiority in dynamic strength and durability.

The new triple rip-stop canopy material has an advanced coating to increase strength, rigidity and durability while improving feedback to the rider for a more direct feeling.

The technical triple rip-stop dacron is incredibly strong and reliable. It’s used in areas requiring rigidity and stability, the leading edge, struts, wingtips and reinforcement areas.

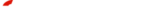

NO pulleys, NO problems. We design all our inflatable kites without pulleys, to inherit the unique Ozone feeling and performance across our range.

The Leading Edge features Transverse Sail Shaping creating a cleaner surface on the most important area of the aerofoil. The result is less turbulent airflow and longer skin adhesion, which positively effects the lift to drag ratio increasing overall performance.

Overlap flat seam construction improves sail control resulting in an overall cleaner canopy.

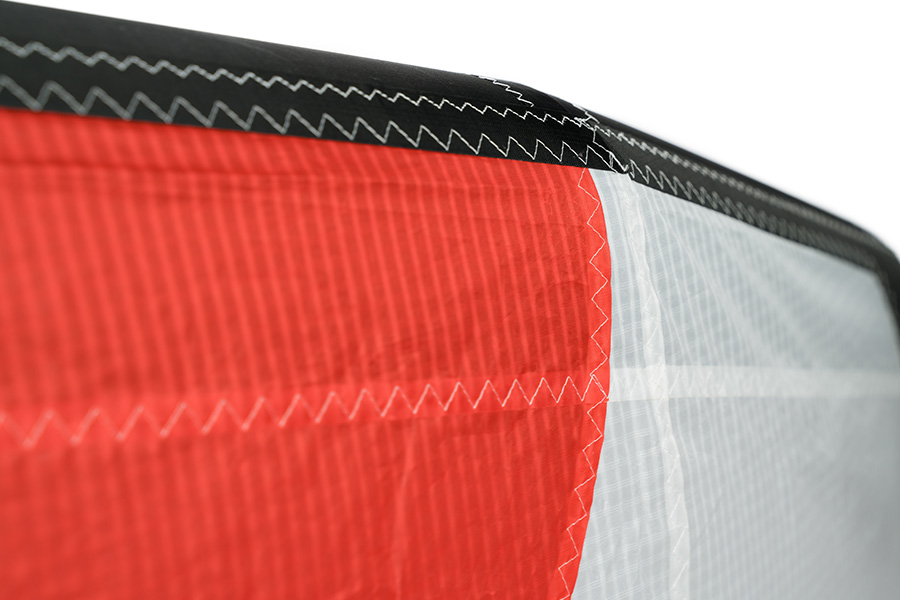

What’s on the inside counts too – internal reinforcements for improved strength and durability; such as a Double layered Dacron + Insignia taped Leading Edge closing seam with high strength threads.

Dacron reinforcements are used on all loaded areas for enhanced load distribution. This means all loads are spread evenly into the sail ensuring the kite flies and performs at its best.

Our Direct Connect construction method improves load distribution between the Leading Edge, Struts and Canopy. Struts are connected directly to the Leading Edge with internal and external reinforcements. This unique construction method ensures clean profiles are maintained with the optimum canopy tension.

The Leading Edge and Struts are reinforced in high stress areas to ensure the kite canopy remains in shape and performs at its best.

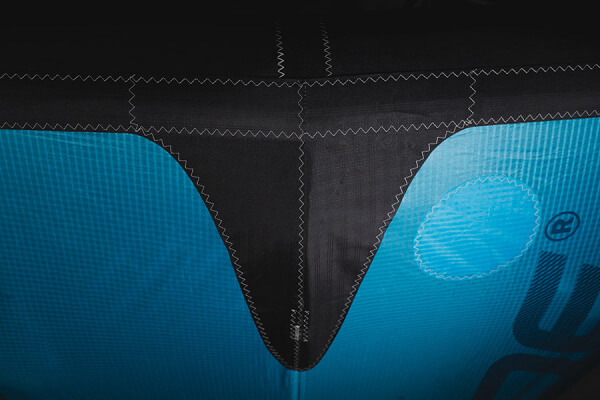

Double layer Trailing Edge strip with an internal light weight Dyneema reinforcement – this reduces canopy wear and helps to maintain optimum Trailing Edge tension as designed. The Dyneema line also reduces any potential stretch at the Trailing Edge.

Leading Edge bumpers are often large and unnecessary cosmetic items. At Ozone we build our kites and wings for performance and durability using the best materials & components available. Any areas requiring scuff protection we use a lightweight durable material with superior abrasion resistance, while keeping a low profile in order to reduce drag and maintain performance.

Our bladders are constructed in-house with advanced custom built welding machines. Double layered sections are applied to any potential wear areas.

The Anti-Snag line deflectors prevent bridles and lines from tangling around the wing tip. Safety is increased when launching with a partner and water re-launch is made easier.

We work extensively during our R&D process to develop the size range to feel in tune with each other. Every kite has a unique bridle layout, individually tested and fine-tuned to maximize the feeling and performance.

The Fast Flow One-Pump Inflation System makes set up and packing quick and easy. It features single point inflation/deflation and a high air flow rate between the Struts and Leading Edge, with clips to seal the hoses to prevent unwanted air flow in case of damage.

Soft Battens strategically positioned along the Trailing Edge provide canopy support and reduce flutter, enhancing kite feedback to the rider and also reducing canopy material wear.

Customise your handling and bar pressure with the back line bridle attachments. Closer to the Leading Edge for slower turn speed and more bar pressure, or closer to the Trailing Edge for faster turn speed and less bar pressure.

Fool proof line connectors prevent incorrect rigging of the flying lines to the kite.

High performance Technora bridle lines offer a vast reduction in parasitic drag and reduced weight.

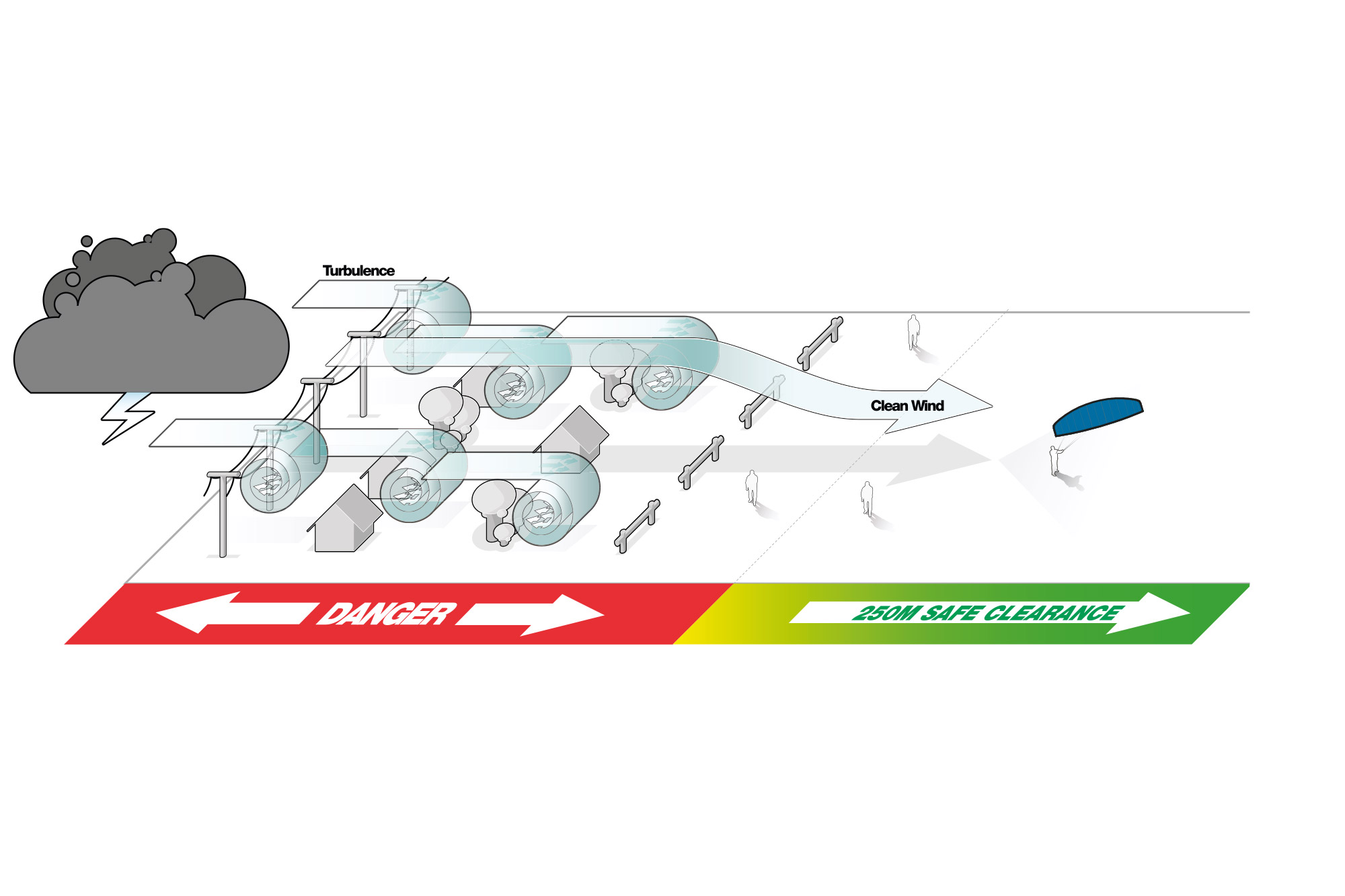

At Ozone we are passionate about sports, and it is this passion that drives our design team to perfect and develop products that we love to ride with. We are proud of the quality of our products, and are constantly searching for the best components and materials to use in our designs. We manufacture in our own high-quality production facility in Vietnam, which guarantees a build quality that we are proud to put the Ozone name on. A close look at one of our products reveals that same superior quality and construction that ensures that every Ozone product will enjoy a long life, with consistent performance and aesthetics. To view the factory video visit our website www.flyozone.com. Many dynamic action sports carry inherent risks but with common sense and education from qualified instructors means you can easily enjoy these incredible sports. Accidents generally happen due to a lack of experience, changing weather conditions or from using equipment not suited to the riders’ ability and/or conditions. Always take the time to learn safely with qualified instruction and you will progress far quicker. Ride safe Team Ozone

By assembling and/or using this Ozone product, you agree that you have read and understood the entire Ozone product owners manual, including all instructions and warnings contained in that manual, prior to using the Ozone product in any way. You additionally agree that you will ensure any additional or subsequent user of your Ozone product will read and understand the entire Ozone product owners manual, including all instructions and warnings contained in that manual, prior to allowing that person to use your Ozone product.

Use of the Ozone product and any of its components involve certain risks, dangers, and hazards which can result in serious personal injury and death to both the user and to non-user third parties. In using this Ozone product, you freely agree to assume and accept any and all known and unknown risks of injury to you and third parties while using this equipment. The risks inherent in this sport can be greatly reduced by abiding by the warning guidelines listed in this owner manual and by using common sense.

In consideration of the sale of the Ozone product to you, you herby agree to the fullest extent permitted by law, as follows;

TO WAIVE ANY AND ALL CLAIMS that you have or may in the future have against Ozone Kitesurf LTD or Ozone Kites LTD and all related parties resulting from use of the Ozone product and any of its components.

TO RELEASE Ozone Kitesurf LTD or Ozone Kites LTD and all related parties from any and all liability for any loss, damage, injury or expense that you or any users of you Ozone product may suffer, or that your next of kin may suffer, as a result of the use of the Ozone product, due to any cause whatsoever, including negligence or breach of contract on the part of Ozone Kitesurf LTD or Ozone Kites LTD and all related parties in the design or manufacture of the Ozone product and any of its components.

In the event of your death or incapacity, all provisions contained herein shall be effective and binding upon your heirs, next of kin, executors, administrators, assigns, and representatives. Ozone Kitesurf LTD or Ozone Kites LTD related parties have not made and expressly deny and oral or written representations other than what is set forth herein and the Ozone product owners manual.

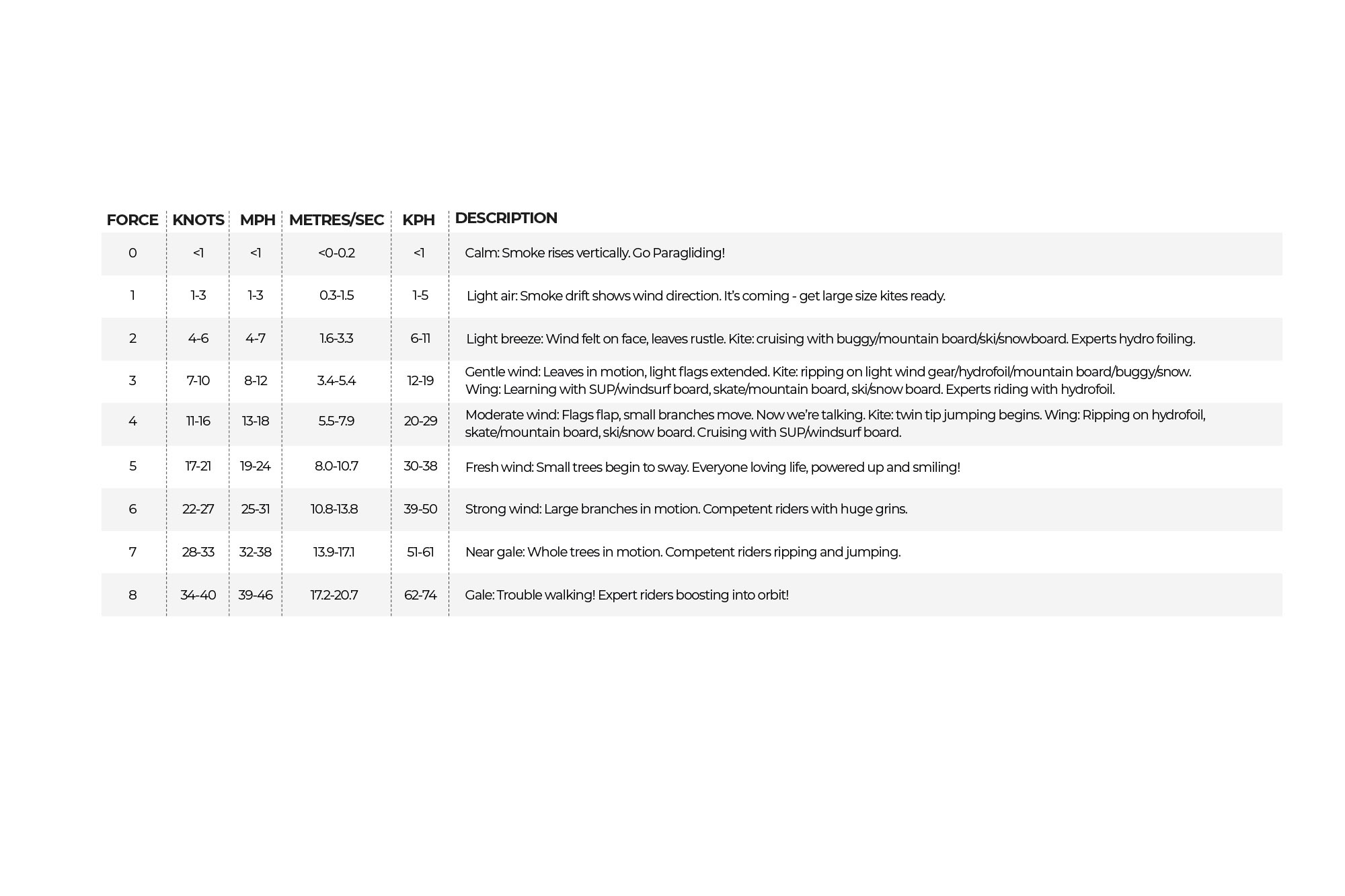

A: Pump Leash

B: Leading Edge

C: Trailing Edge

1 & 4: Back Lines

2&3: Front Lines

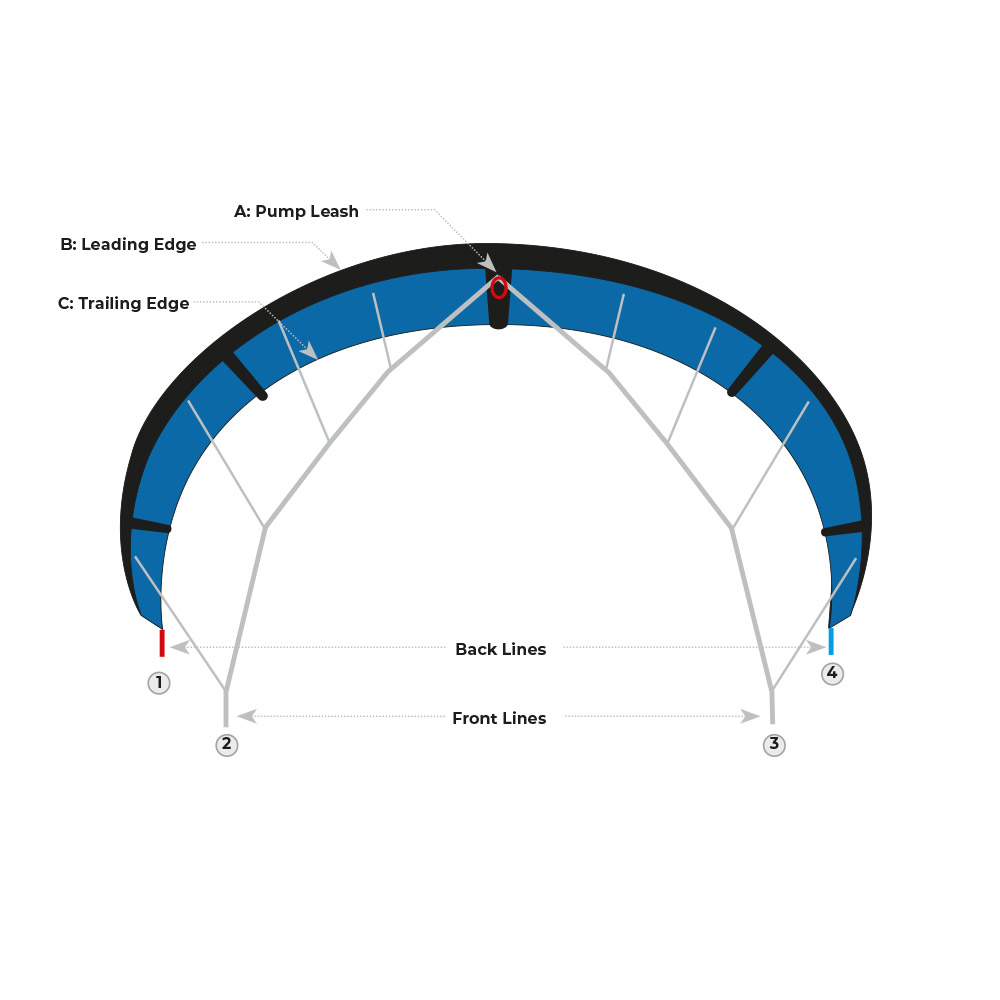

1 & 4: Back Lines

2&3: Front Lines

A: Clamcleat Trimmer

B: Flag Out Line

C: De-Power Line

D: Quick Release Handle

E: Quick Release Loop

F: Flag-out Loop

G: Finger

Do not ride the kite with the one pump clips undone. If you get a puncture the whole kite will deflate! Always close the one pump clips inside the neoprene covers after pumping up. Do not under inflate the kite or it will not perform to its designed trim and will not relaunch easily.

Always double check your lines before launching. Wrongly attached lines will stop the kite flying correctly and could therefore mean you have no control of the kite putting yourself in a dangerous situation.

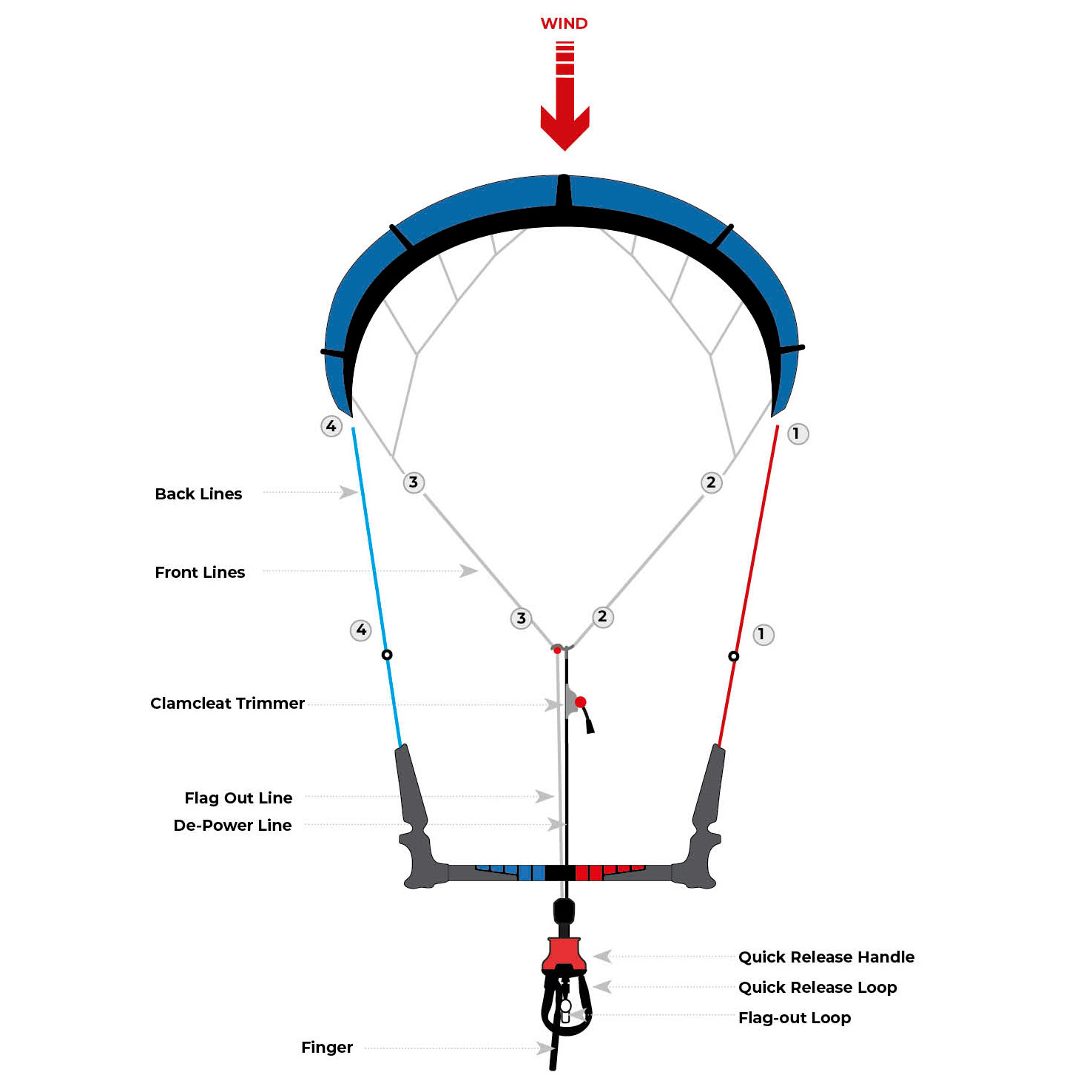

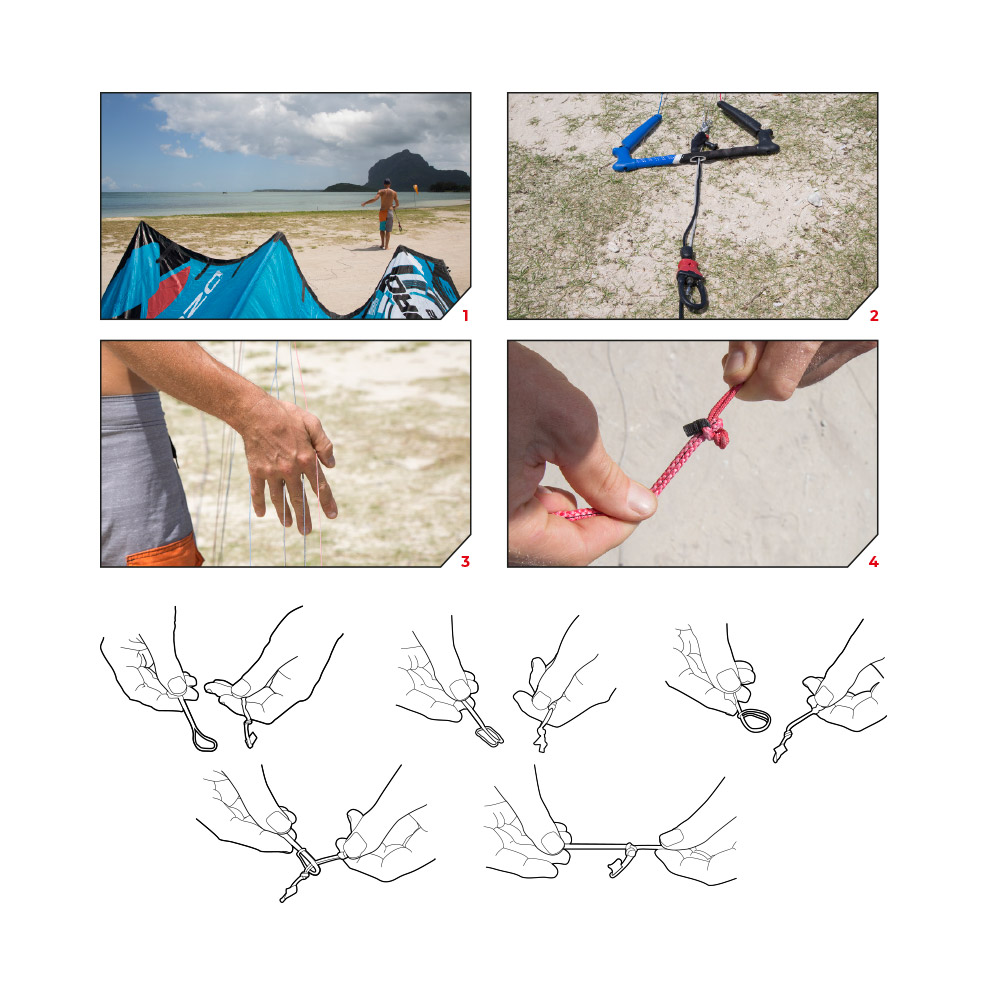

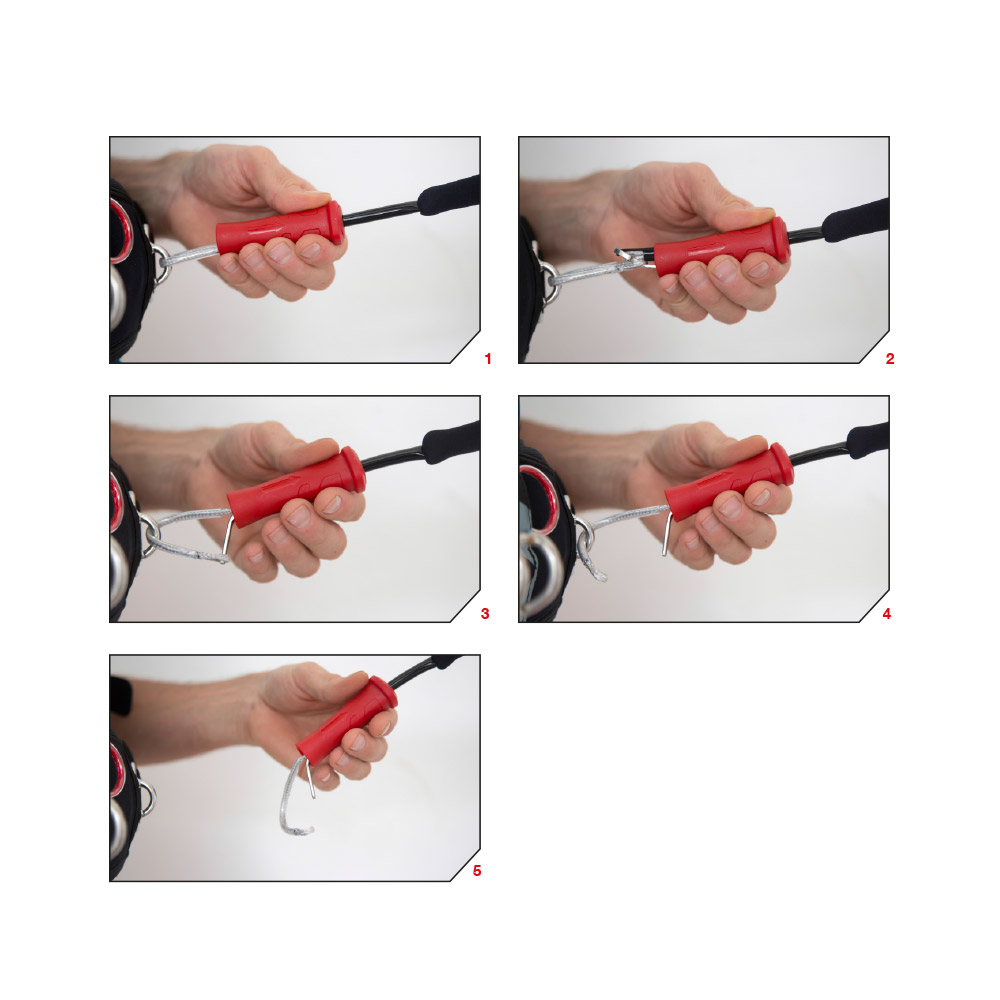

The Quick Release is the primary connection to the kite. Make sure you connect to the Quick Release using the finger as shown in the pictures.

All riders should attach their Kite Leash to the Flag Out System. This is the small eyelet on the Stainless Steel Swivel Ring.

When the release is activated, the kite will flag out and fall to the water/ground.

In all situations make sure that all lines are clear of all working release systems and the kite leash is connected in the right way.

Riders performing unhooked tricks or who are more confident and have spent many hours Kiting can attach in Expert mode, where the loop part runs through the large eye of the steel ring. When letting go of the bar in Expert mode (without activating the release e.g. missed handle pass) the kite will depower but WILL NOT flag out.

Be aware in this situation, the Quick Release will be out of reach and can therefore not be released. When hooked in and activating the Quick Release the steel ring automatically slips off and the kite will flag out.

Activate the Quick Release as shown in the pictures. Providing your leash is attached to the flag out system the kite will 100% depower.

In the case of an extreme emergency where you need to completely release from the kite, use the quick release on the kite leash. This will completely detach the kite and control system from the user, and could therefore hit anything or anyone downwind causing damage, serious injury or death. RIDE RESPONSIBLY.

WARNING:

NEVER LAUNCH A KITE DIRECTLY DOWNWIND OF YOU IN THE POWER ZONE!

Instruct your partner on how to handle the kite and agree on a sign together for the release and landing. They should hold the kite in the center of the leading edge at the edge of the window and double check that all lines are clear. It is possible for lines to get wrapped around the tip so make sure they understand that all lines must run clearly from each attachment point.

Before you give the signal to release make sure you are 100% confident that all lines are clear. Then give your pre-agreed signal for your partner to release the kite and gently launch the kite to the top of the window.

Landing the kite use the same principles >> Most importantly keep your head clear, be smooth and controlled with the kite and land before you are too tired or overpowered.

WARNING:

Make sure you grab the correct side of the bar

– we colour code the bar red for left.

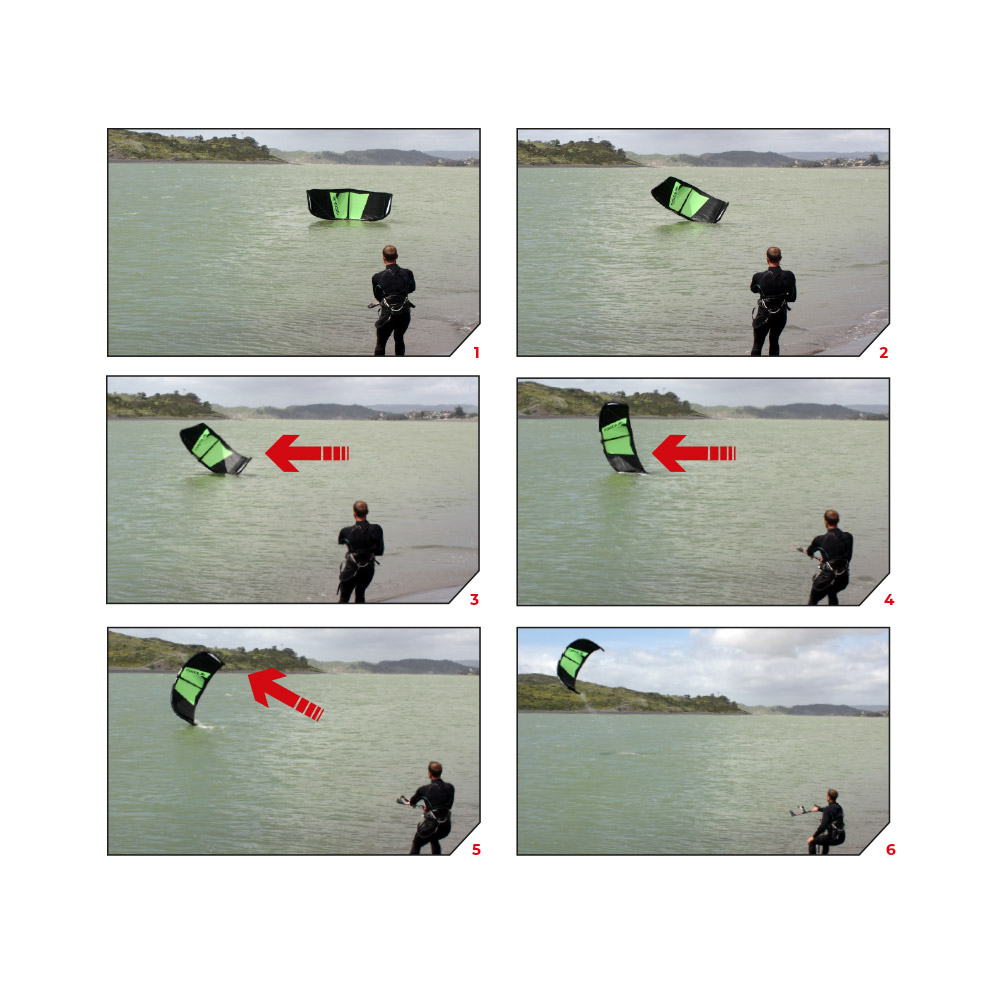

Once the kite is face down with the leading edge touching the water:

NOTE: If the kite somehow lands nose down but with the tips facing away, pull one of the rear leader lines to help the kite blow around to the correct position then follow the steps above for getting the kite re-launched.

If you get in trouble out in the water, there is a simple way to self rescue yourself.

Firstly kill the kite’s power with the flag out system by releasing the chicken loop. The kite will flag out and drop to the water.

Lines are dangerous in this situation so make sure you wind the flag out frontline around the bar at least 10x to disable the kite. Then wrap all the lines together onto the bar as you normally would. You will end up at the kite ideally with the lines wrapped tightly and neatly on the bar. Make a few half hitches to secure the lines.

Once you have got hold of the kite you can drop the bar. When you have reached the kite, take hold of the bridle lines at each wingtip. Hold both bridals to use the kite as a sail to get back to shore safely.

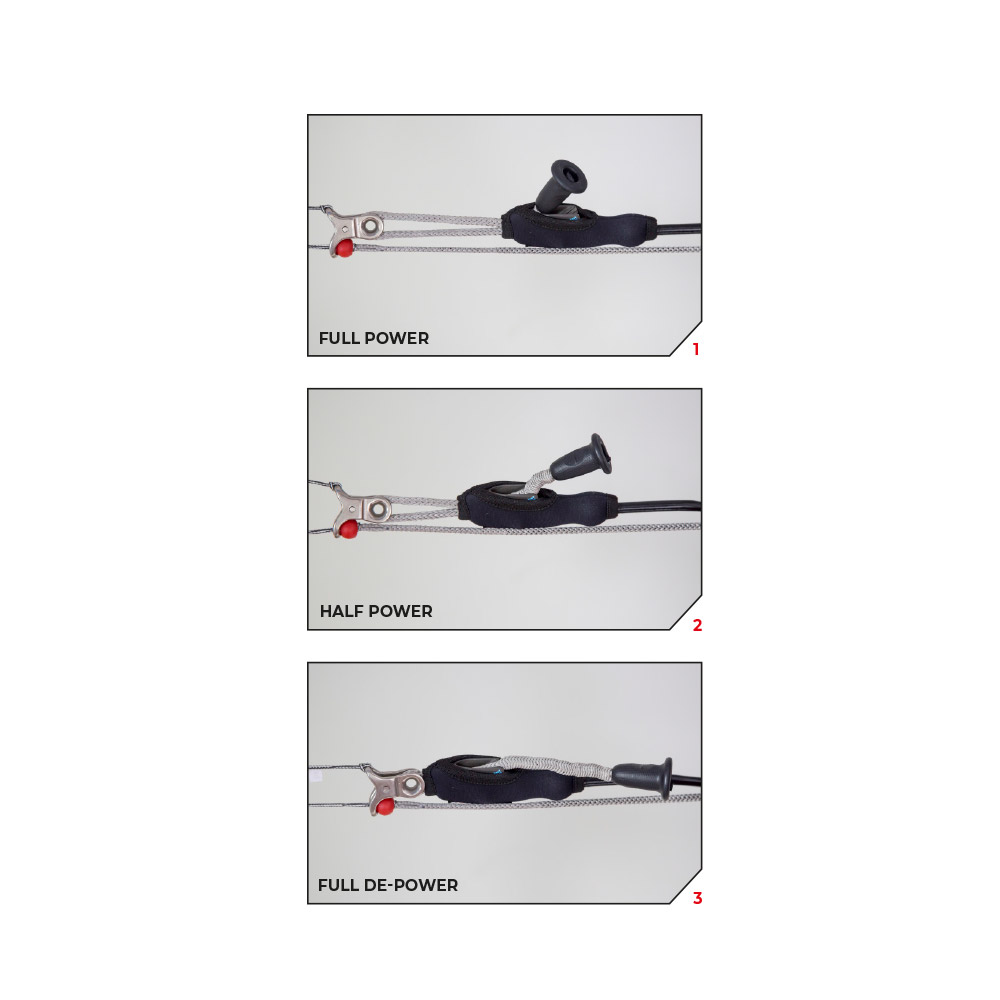

To release the line from the cleat teeth, first pull out and down to unlock the line from the teeth, then set the trimmer line to the desired amount.

Pull the trimmer line down to de-power the kite. This is needed if you are overpowered, for unhooked riding, or if you are walking on the beach or snow.

Release the trimmer line away from you to increase kite power.

1: FULL POWER

2: HALF POWER

3: FULL DEPOWER

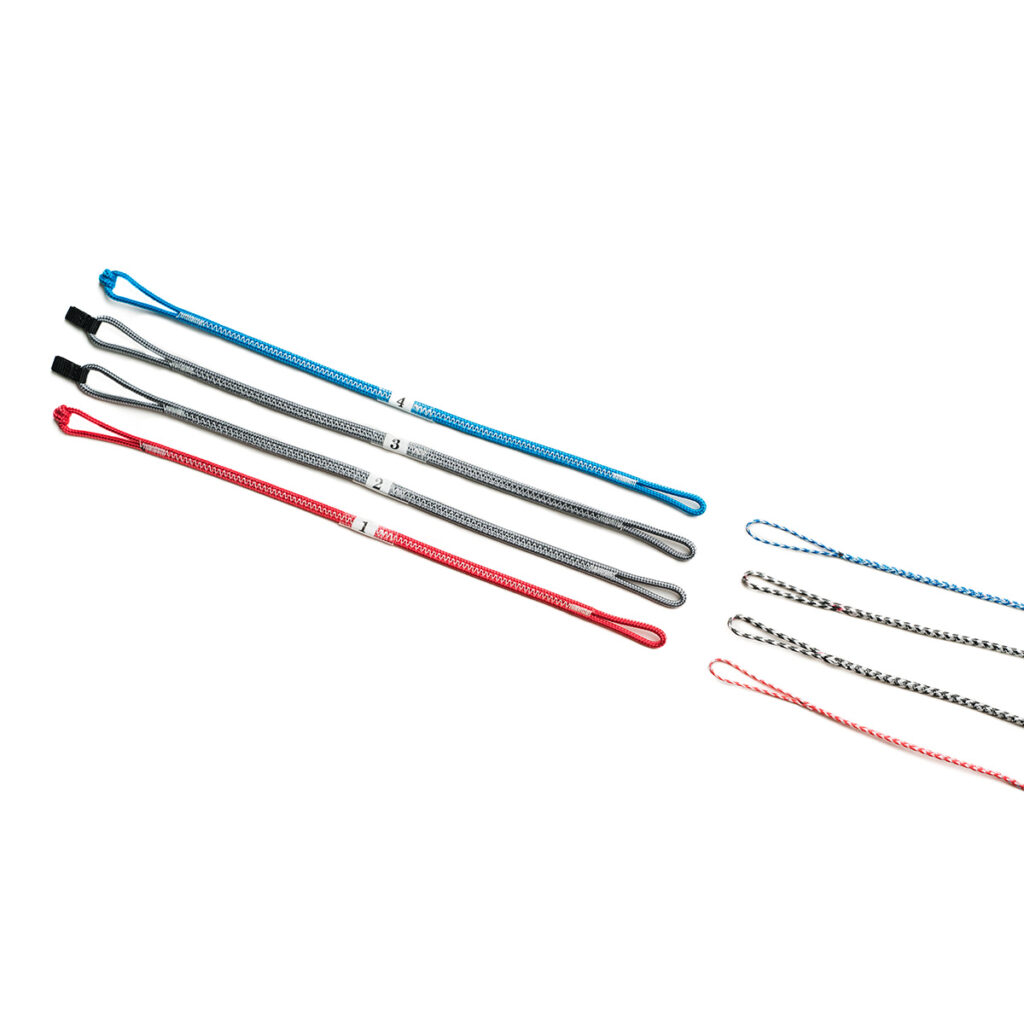

All lines should be maintained as close to equal length as possible. Flying lines can stretch over time, generally the front lines stretch more as these take the majority of the load.

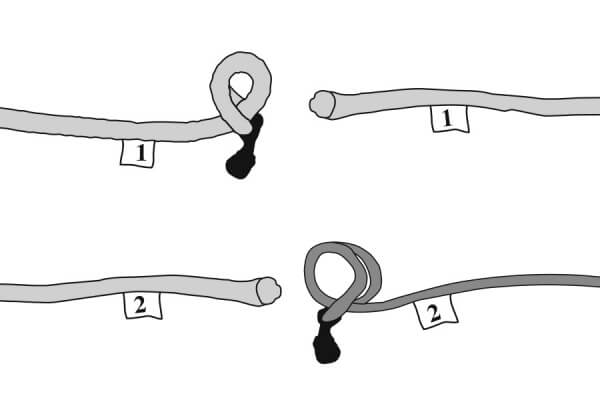

To check your lines, unwind the lines from the bar and have a partner hold the lines even at the bar end. Taking hold of the lines at the other end, pull on the lines to check they are even. If the lines are not even you may either;

1) Stretch out the shorter lines. Attach the shorter lines to a car hitch or something very solid. Then take hold of the bar and pull with enough force to stretch the line. Do this to any lines that are shorter and re-check that all 4 lines are equal length.

2) Use the Leader Line trimming knots located underneath the bar ends.

Kites are very technical products and are used in the harsh marine environment. If you use common sense and care for your equipment it will look after you and keep its factory trim for hundreds of hours.

Never pump up your kite on a rough surface which may have sharp objects.

Be very careful with your flying lines. If you catch them on a rock or sharp object thoroughly check each one and we recommend you replace your lines. Also make sure there are no knots in the lines. Knots weaken the line by up to 50%.

Once you have pumped up secure your kite with sand or use sandbags – Do not use heavy objects or even your board, the fins have been known to rip kites.

Never leave your kite on the beach un-used for long periods of time in the sun and wind. The trailing edge flapping and sand hitting the sail cloth will severely shorten the kite’s life. UV also shortens the lifespan of a kite so pack away when not using your kite.

Never pack away your kite wet, only when 100% dry – This will damage the cloth and its coatings and may lead to dye running. This is not valid for warranty.

Never leave your kite inside your car in direct sunlight.

Always clean your control system with fresh water after every session, and reload/release the Quick Release to check the system is functioning correctly. Store your control system with the Quick Release open. Reload the next time you set up your kite.

When inflating the bladders always inflate slowly and ensure the bladders are inflating correctly in the struts or leading edge. If you see a twist or something looks strange STOP pumping immediately and check bladders. They may need re-inserting to ensure they inflate properly.

We supply a repair kit with the following contents:

1. A4 pieces of sail cloth

2. A4 piece of Dacron

3. 1 x length of 50mm wide sticky black repair tape

4. 6” x 3” Tear-Aid bladder repair patch

5. 2 Alcohol wipes

6. One pump clip / hose / hose retainer

If you have a major repair like a tear across panels, struts or the leading edge take the kite to your local sail repair shop. For minor tears and bladder punctures you can easily fix these yourself with the repair kit supplied with the kite.

All Ozone products are made to order in our own factory in Vietnam and sold through our trusted dealer network, who deliver excellent customer care and advice.

We don’t over produce and instead believe in a sustainable business model that respects people as well as the planet. Although you can't buy gear directly from us, we aim to be as transparent as possible with you about how long the production process takes.

To try and give you the fastest service possible, scroll down to check if we currently have your preferred size and colour in our small factory stock that can be shipped to your dealer immediately.

We also offer custom colours for all our kites and wings. Try your ideas out using the custom colour chooser further down this page. Once you’re happy with your design, copy the colour code and send it to your local dealer through this contact form. They will be in touch ASAP.

If you’re desperate to get your hands on a product as soon as possible, contact your nearest dealer to see if they're currently holding any stock. Click here to locate them and get in touch.

We can make any combination of colours using the colour chooser below. The manufacturing time for these special kites is 30 days. Design your kite, share with your friends and ask your dealer to place your order.

Millions of people go to the beach every year and kitesurfing is the most visually spectacular beach sport around, drawing the eyes of attention from everyone. Kites are huge and kites with a customized design can be amazing advertising spaces.

Flying up and down the beach, park or snow all day long, these spaces can be used to advertise local and international businesses, kite-schools or simply for your own kite with a design that suits you perfectly and makes you stand out a little more from the crowd. If you have your own company you can add your company logo to your kites which allows them to be written off as a business operating expense. How cool is that!

For mainstream companies the opportunity to invest in a flying Billboard is obvious at a fraction of the cost to normal advertising. So far we have worked with many of the World’s leading brands making them kites or making kites for riders sponsored by mainstream brands that see the benefit in Kite sports.

Check out some of the custom kite designs we’ve made for customers: custom kite gallery

Quotes vary depending on the complexity and size of the logo or design. We can only give a quote once we have the info (see above)

We screen print any colour – our standard stock fabrics’ or any other pantone – onto white sticky-back rip-stop material. The logo is then cut out, stuck & sewn on the kite or wing. This technique is suitable for mid sized logos that span over a few panels. Please note that it adds some extra weight

We can cut logos into the sail on any single surface kite or wing and even on both surfaces of foil kites. The logos look amazing and the light shines through beautifully. We can either use our standard colour fabrics, or screen print any colour onto white fabric. Price depends on the custom design surface area and how complicated the logo is – not all details of your dream design are possible to build. Ask your local distributor for feasibility and quote

A cutting-edge digital printing technique that’s fast, cost-effective and precise. The process allows ink to be embedded directly into the fabric, resulting in rich, vivid designs with endless colour possibilities. While some minor colour bleed can occur on very close inspection, the stunning results make this a fantastic choice for high-impact graphics on a kite or wing

A clean and simple design, featuring an easy-to-use trim system and our innovative Click-In Loop Quick Release.

Find a dealer

Push-away quick release with an innovative one-step Click-In reload function that is incredibly intuitive. The release handle fits comfortably in the hand, it is quick and easy to activate the release by pushing the handle away. A self-positioning release mechanism locates automatically, ready to be re-loaded by simply ‘clicking’ in the loop. The Click-In Loop is AFNOR NF S52-503 certified.

Colour coded 500kg front / 300kg back lines are precision cut, pre-stretched, spliced and sewn in our own production facility to guarantee accuracy. We use the highest quality Bio-based Dyneema® – this material has the same performance as conventional Dyneema® with a carbon footprint that is 90% lower than generic HMPE fiber.

Our modular design makes adding or removing extensions quick and easy via removable pigtail end connectors.

3D pressed EVA with ergonomic shaping and a lightly sanded finish provide the ultimate bar grip. It is colour coded with the leader lines and flying lines for an added visual safety feature.

What’s the first thing you do when you get in a car? You click in your seatbelt, hearing that ‘click’ sound makes you feel secure that you are safely buckled up, and you know instinctively how to release it. The design of our innovative quick release system, the Click-In Loop, was inspired by the same principle. In the same way fastening your seatbelt has become a natural action when getting into a car, riders should activate and reload their release systems before and after every use. Although this important safety check is often overlooked, checking your release before each session will ensure it is functioning properly. We developed the Click-In function to be simple and intuitive, so activating and reloading will become second nature.

All riders should attach their Kite Leash to the Flag Out System. This is the small eyelet on the Stainless Steel Swivel Ring.

When the release is activated, the kite will flag out and fall to the water/ground.

Riders performing unhooked tricks or who are more confident and have spent many hours Kiting can attach in Expert mode, where the loop part runs through the large eye of the steel ring. When letting go of the bar in Expert mode (without activating the release e.g. missed handle pass) the kite will depower but WILL NOT flag out.

Be aware in this situation, the Quick Release will be out of reach and can therefore not be released. When hooked in and activating the Quick Release the steel ring automatically slips off and the kite will flag out.

In all situations make sure that all lines are clear of all working release systems and the kite leash is connected in the right way.

Always clean your control system with fresh water after every session, and reload/release the Click-In Loop to check the system is functioning correctly. Store your control system with the Click-In Loop release open. Reload the next time you set up your kite.